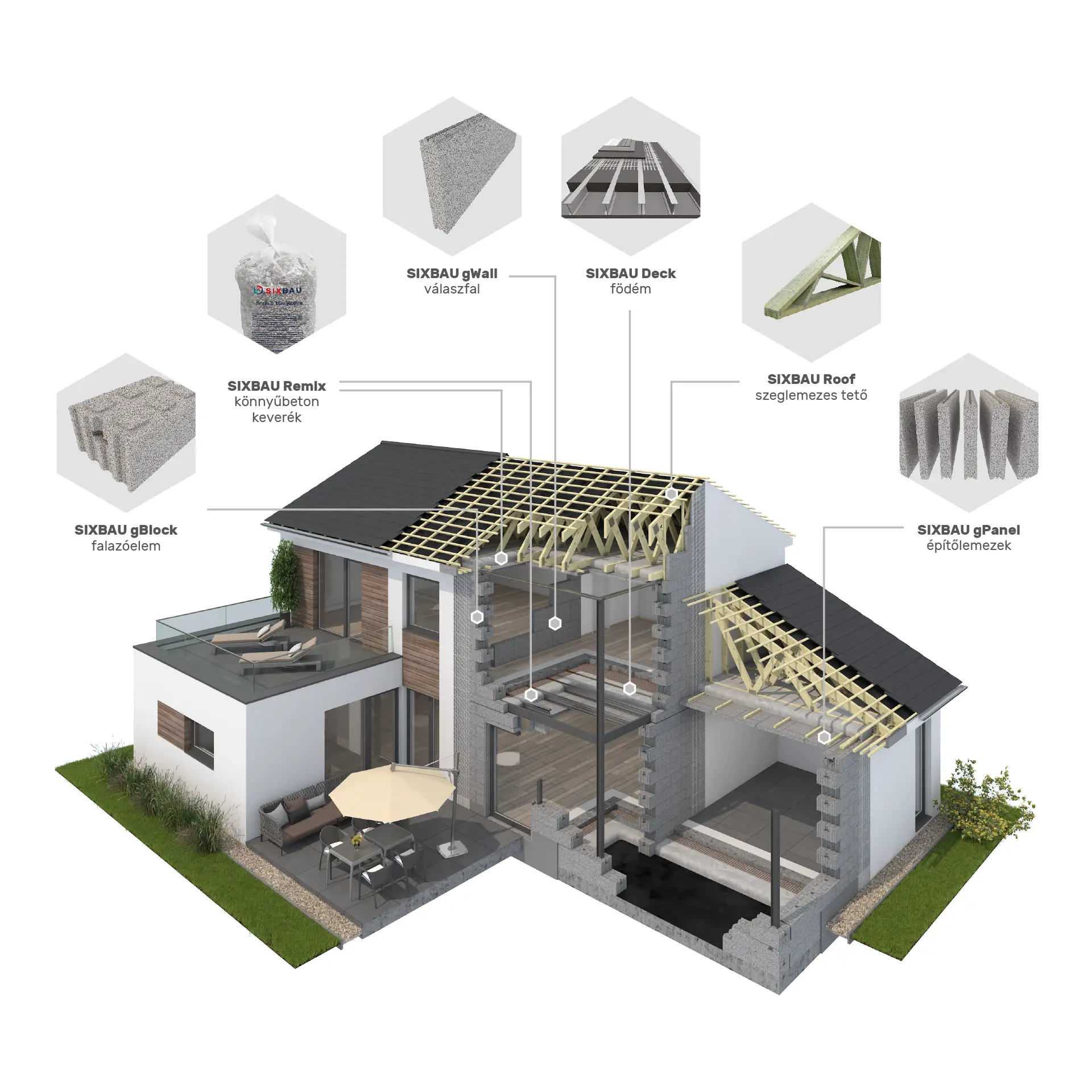

SIXBAU BLOCK

masonry construction systemA traditional construction system based on the use of special large-scale lightweight concrete masonry units.

Our building system is based on the SIXBAU gBlock “brick”, which inherited only its shape from its previous counterparts. The raw material is polystyrene concrete, which has many advantageous properties in the gBlock masonry unit. It provides an excellent feeling of comfort, it has very good thermal insulation properties, therefore it is not necessary to use additional facade thermal insulation in the case of single-layer masonry built from it. Due to its large size, the construction process is faster, which significantly reduces construction time and cost, and its favorable weight ensures easy mobility, so it puts less strain on the worker. The construction system we offer is perfect for the construction of single-storey and multi-storey family houses, condominiums, community buildings, as well as for the construction of reinforced concrete and other frame building structures, hall and factory buildings, industrial and agricultural buildings.

The SIXBAU Block building system can be used to create buildings with excellent energy performance (up to AA +) * and fire safety values. The outstanding advantage of the construction system based on single-layer masonry manufactured by us is that it can provide the expected thermal insulation values even without the use of a retrofit, additional façade thermal insulation system, thus significantly reducing the costs incurred. The basic components of the system are the SIXBAU gBlock masonry element, the SIXBAU gWall partition elements, and the SIXBAU Deck Slab and SIXBAU Roof Slab Roof. As all the building materials and building components required for a prefabricated building are procured from a single partner, aquisition and logistics are simplified during construction, which also saves a lot of time and money.

* Consult a specialist to determine the energy rating of your building.Construction process

1. Planning

A construction is a long process, each step of it is decisive for the building and its future occupants. After the decision is made, the first step is to start working together between the builders and the designer, which will result in a plan for the building. Based on the plans, the budget will be prepared and any amendments will be made. Based on the plans, our designers prepare the design documentation for the SIXBAU BLOCK building system, which includes the construction plans, detailed drawings, junctions, material collection, calculation, as well as all the necessary technical information on the basis of which the planned building can be built.

2. Foundation

The first step in the construction, is to prepare the foundation of the building. We do not take part in the preparation of the foundation plans and the subsequent construction work concerning the foundation, but we consider it is important to emphasize that errors and inaccuracies in the foundation can cause many difficulties in the future, therefore we consider it extremely important to work in accordance with SIXBAU standards.

3. Masonry

Once the foundation and insulation against the soil moisture have been completed and taken over, the construction of the masonry of the building will begin. If a two-storey building is being constructed, the vertical steel pillars will be placed before the masonry begins, followed by the placement of the starting row, which will require increased attention and care. If the laying of the starting line is of good quality, the load-bearing masonry of the building as a whole can be completed in a very short time.

4. Roof receiving structure

After the completion of the masonry work, the preparation of the horizontal wreath, the placement of the building structures and fittings suitable for receiving the prefabricated nailed roof structure during the finishing of the finished load-bearing masonry, can be completed.

5. Roof installation

Delivery, assembly or installation of a prefabricated nailed roof structure according to the SIXBAU BLOCK construction system, usually takes no more than a day or two. All the roofs we manufacture are made in continuous factory quality under continuous quality control, and we issue a quality certificate for each roof we manufacture, which is also a guarantee for our prefabricated nailed roof structures.

6. Lightweight concreting

Our nailed roof structures are also the closing slabs of the building, the insulation and rigidity of which is ensured by the casting made after the assembly of the roof structure. The assembly of the roof is thus followed by the final design of the ceiling and slab, which consists of the placement of the remaining formwork made of SIXBAU gPanel building boards and the subsequent lightweight concreting, ie pouring. After this, the tiling, the necessary foiling, tinning and peeling can be done.

7. Finishing work

Finishing work can begin on the finished building, after the installation of the doors and windows. The building engineering works, the design of the external internal plastering and surface formations, painting, cladding, assembly can begin.

8. Key handover

Once the finishing work is done, the final touches will be done and handed over to the new home you have dreamed of.

_007.webp)

_010.webp)

_020.webp)

_025.webp)

Facebook

Facebook Youtube

Youtube